Driving your CtP

At A Glance

Computer to plate has changed the way plates are produced, especially regarding the deadline.:Apogee Prepress and PlateMaker support any CtP device to deliver plates in time before the press starts.Using Apogee Prepress, there are three ways to drive your CtP. Either the CtP device is supported directly out of the :Apogee Prepress workflow, or the plate ready data is sent to PlateMaker, which operates as a digital buffer, or the plate ready data is sent to a third party CtP device.

Apogee Platemaker is targeted to the high end, high volume printers who need a maximum plate production, which is load balanced over multiple CtP devices.

Applies To:

Apogee Render, Apogee Control, Apogee Manage, Apogee IntegrateHow It Works

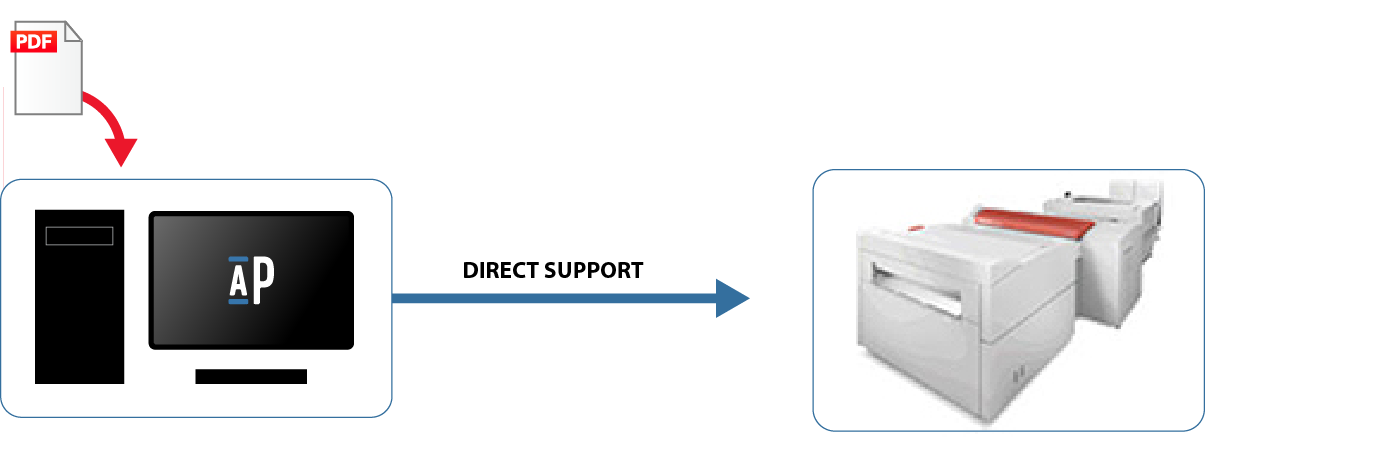

1. The Ctp is directly supported by the Apogee Prepress workflow.Apogee Prepress supports a wide range of Agfa and non-Agfa CtP device using an integrated connection. Due to this direct link, a two-way communication is possible where Apogee Prepress not only sends the plate data, but also CtP device specific commands. The CtP-device on its turn will also feedback data, such as the amount of exposed plates back to the Apogee Prepress system.

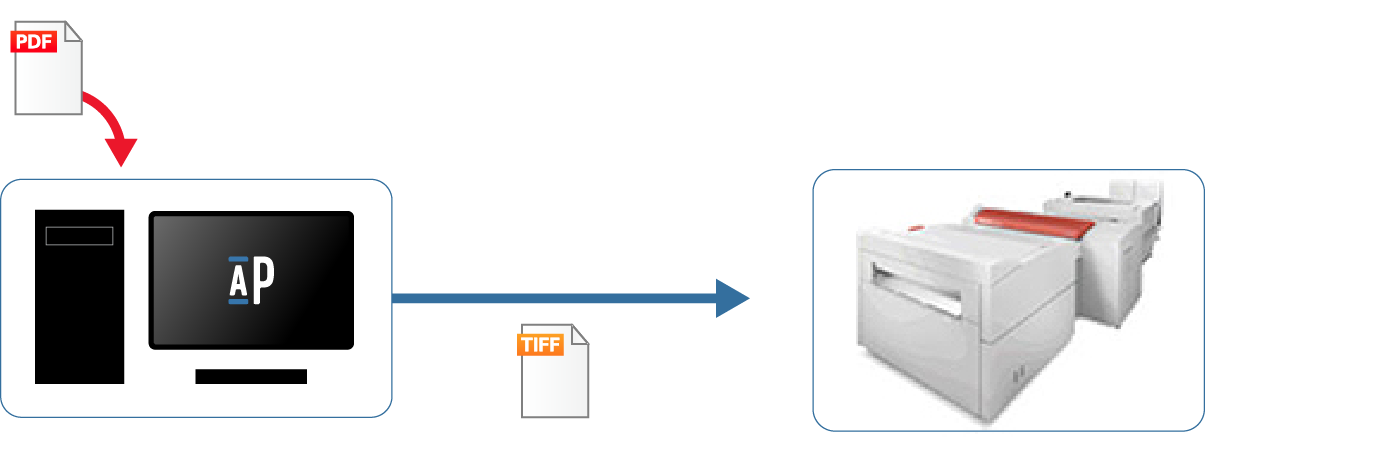

2. Plate ready data is sent to Apogee Platemaker

The main purpose of Apogee Platemaker is to have a plate output independently from the Apogee Prepress system.

Plate ready data is sent to the Platemaker system, together with JDF/JMF data. Possible, the main Platemaker system is acting as the server, while other Platemaker systems are acting as satellites.

Having an independent plate processing will guarantee a secure environment, which does not rely on Apogee Prepress anymore.

Apogee Platemaker is also able to accept 1 bit TIFF files from third party workflows.

Apogee Prepress will send plate ready data (1 bit TIFF) together with JDF/JMF data to the Platemaker software. Apogee Platemaker will act as a hub which collects all the data and spread it out over multiple Platemaker systems (load balancing). Also, all plate data is stored, so plate remakes are easy to perform. Apogee Platemaker also has extra functionality as standard such as job (re)scheduling, job queuing, re-directing CtP devices, back-up & restore.

The Platemaker software is able to give feedback of the plate processing using JDF/JMF.

3. Plate ready data is sent to a third party CtP Device.

Using the 'Non-Agfa Output Link' enhancer, Apogee Prepress is able to send plate ready data to third party CtP devices. With this solution, Apogee Prepress can be seamless integrated within a third-party environment.

RSS

RSS